By Willie Sandry

Willie Sandry is a Freelance Writer, blogger, and crafter who loves having the right tool for the job.

This article is intended for educational purposes only. Leather Hide Store does not recommend or endorse any leather sewing products.

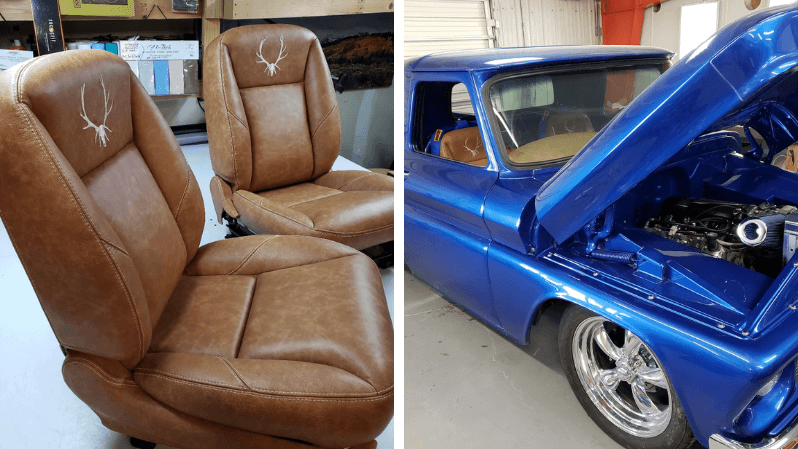

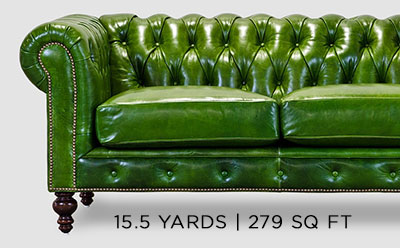

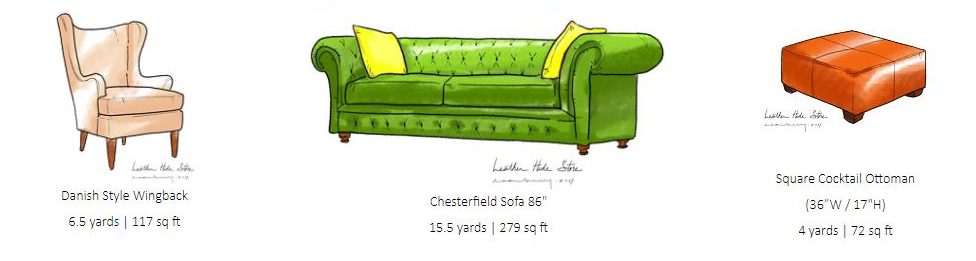

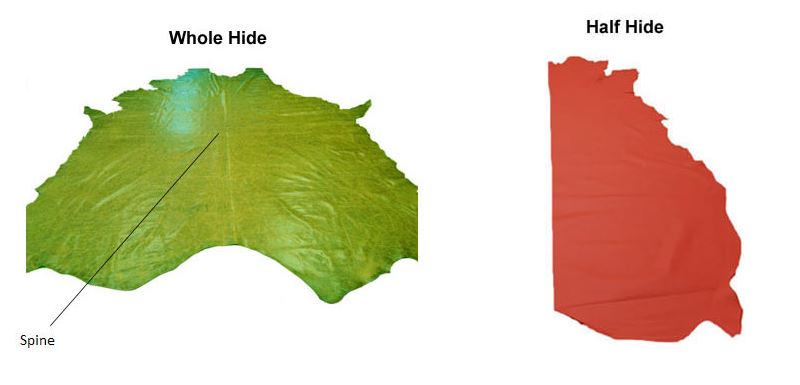

You've chosen the perfect leather, consulted The Ultimate Reupholstery Guide, and you're ready to jump into your project. Whether you are a seasoned leathercrafter, or new to the game, these tips for choosing the right sewing machine can help make your future projects a cinch.

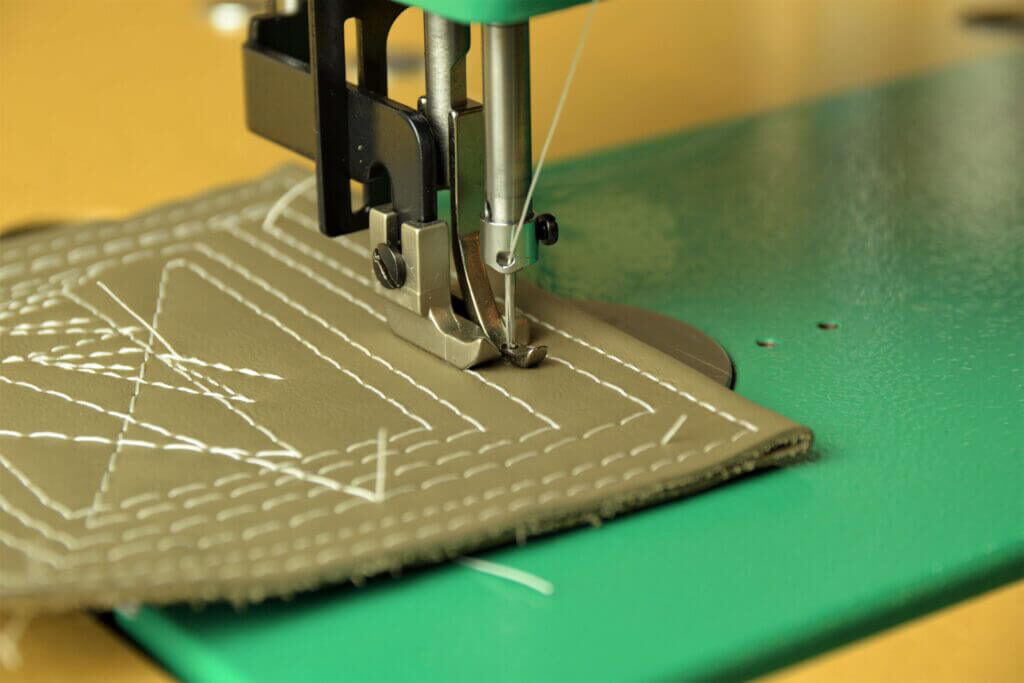

1. A Walking Foot. Sewing leather opens up a number of avenues for crafters and upholstery enthusiasts. The problem is, a home sewing machine doesn’t have the right feeding mechanism to handle leather. A domestic machine is limited to drop feed, which means the material is pulled through by feed dogs alone. Not only can this fail to adequately feed the material through the machine (which causes shortened stitches) but it also tends to advance the layers unevenly (leading to uneven edges and wrinkles sewn into your project). The number one most important feature to sew leather is a walking foot mechanism. Let me be perfectly clear here… I’m not talking about a walking foot attachment for your home sewing machine. A true walking foot is an integral mechanism on a sewing machine that pulls material from both the top and bottom for even feeding. A walking foot has feed dogs below, and alternating presser feet above, to consistently feed leather without issues.

2. A Servo Motor. Let’s talk motors for a minute. A home sewing machine has a small variable speed motor that can handle light and medium-weight materials. The fact that it has variable speed is good, but it just doesn’t have the power for sewing leather.

A large industrial machine might have an old-fashioned clutch-style motor. You’ll know it’s a clutch motor if it hums whenever it’s powered on. While clutch motors are certainly powerful, they’ve fallen out of favor because they’re very difficult to control.

The solution to these problems is a variable speed servo motor. With plenty of punching power, while still being easy to control, a modern servo is a crowd favorite. Typically rated at 550 watts (3/4 h.p.) they won’t miss a beat with multiple layers of leather.

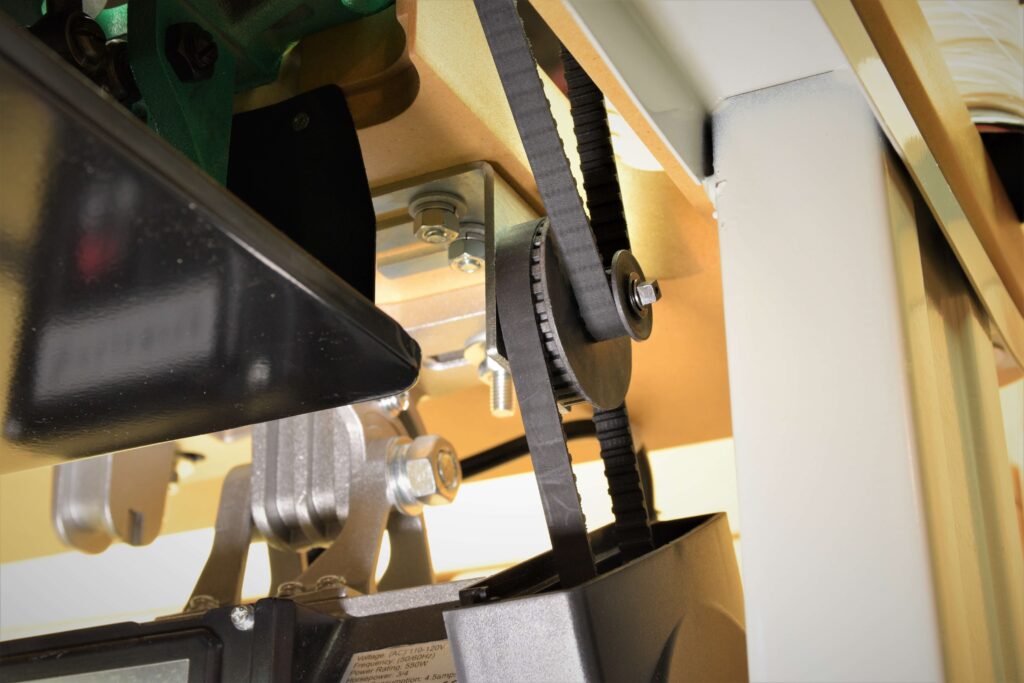

3. Speed Reducer. Have you ever tried to climb a hill on a BMX bike? You know the kind with only one gear? A speed reducer changes that experience to cruising in low gear without breaking a sweat. Basically, a speed reducer is a pair of pulleys and belts that further slow the sewing experience for the ultimate in control. The speed reducer acts as a torque multiplier, which is an added benefit when sewing thick leather. This is especially beneficial when walking over seams and transitions in leather.

Traditionally, a speed reducer was an add-on feature, but some manufacturers are now including it with sewing machine packages designed for leather work.

4. Clearance Under Presser Foot. Make sure the foot lifts high enough on your machine to allow clearance for thick assemblies. If the presser foot lifts nice and high, it will let you place and begin sewing leather with minimal effort. Luckily, leather compresses somewhat as it’s sewn, so as long as the layers slide under the presser foot, you should be good to go.

5. Ability to Equalize Forward and Reverse Stitch Length. Leatherworkers want the forward and reverse stitches to plunk right into the same holes for the cleanest possible look. Every time you terminate a visible seam, you’ll back-tack a few stitches to lock it in place. This is where equal forward and reverse stitch length is so important.

Some machines have this feature, however the adjustment process is so complicated you’d have to be a sewing machine mechanic to get it right. Recently, manufacturers have addressed this common complaint, and solved the issue with easy to adjust stitch length. Simply set forward and reverse stitch length equally and test on a scrap of leather. On this machine, the adjustment is made with two knurled thumbscrews on the front of the machine. The thumbscrews limit travel of the spring-loaded reverse lever as you sew.

Precise Stitch-by-Stitch Control. The combination of a speed reducer and variable speed servo motor result in a relaxed experience behind the sewing machine. With the right equipment, sewing leather can be an incredibly rewarding pursuit.

Start Simple. As with any new craft, start with beginner projects that let you experiment with the machine settings. Here, two layers of leather are sewn together with contrasting thread for a rustic drink coaster. Once you’re familiar with your new machine, go wild with more advanced and functional projects!